Vacuum Drying Solution

Rotary Vacuum Paddle Dryer

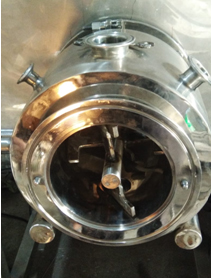

Rotary vacuum paddle Dryer or Paddle Dryer is used to obtain dry Powder from wet cake or solutions. The efficiency is very high and the operating costs are low compared to other types of dryers. It is a closed system in which hot water ,steam, or hot fluid is used as a heating medium in the jacket, in the hollow paddle and in the hallow shaft. Dust collector, condenser, receiver and vacuum pump are part of the system. The continuous agitation by means of heated rotating paddles and minimum clearance between scrapers and heated walls provide a good heat transfer to the wet feed. This results in the solvent/moisture evaporating off and renders the wet material dry, to the required degree. The vapors formed are removed by means of vacuum. Absence of large air flows virtually eliminates dust problems and also the energy consumption remains low. Some of the salient features of a Rotary vacuum paddle Dryer made by us are described below

Rotary vacuum paddle Dryer or Paddle Dryer is used to obtain dry Powder from wet cake or solutions. The efficiency is very high and the operating costs are low compared to other types of dryers. It is a closed system in which hot water ,steam, or hot fluid is used as a heating medium in the jacket, in the hollow paddle and in the hallow shaft. Dust collector, condenser, receiver and vacuum pump are part of the system. The continuous agitation by means of heated rotating paddles and minimum clearance between scrapers and heated walls provide a good heat transfer to the wet feed. This results in the solvent/moisture evaporating off and renders the wet material dry, to the required degree. The vapors formed are removed by means of vacuum. Absence of large air flows virtually eliminates dust problems and also the energy consumption remains low. Some of the salient features of a Rotary vacuum paddle Dryer made by us are described below

- Common base frame is unique to this system. This eliminated the need of foundation cost and reduces the maintenance cost.

- Drying optimization, this is done by means of external and internal heating. External heating is by means of jacket or limpet coils, while internal heating through a hollow shaft and a set of hollow paddles. Hallow paddles are provided with scrapers having very low gap from wall to maximize heat transfer.

- Scrapers move material to all parts of the dryer and also help in discharging the material.

- The hollow rotating agitator shaft imparts heat to the product, scrapes the shell wall, tumbles the product for maximum heat transfer and discharge product when required.

- The large heat transfer area available on the wide paddles and hollow shaft give maximum heat transfer efficiency to the product.

- Mechanical seals at Shell ends/Stuffing Box.

- The vessel is well design to take temperature stresses during vacuum drying. Low power consumption by the use of helical bevel gear box.

- Special floating bearing design to combat temperature stresses.

- To remove the condensate formed by steam heating in the hallow shaft, Special rotary joints are also designed to introduce heating media in the hollow shaft.

- Product Filter is very efficiently used to arrest valuable product carried away with the vapours in a filter bag The arrested product particles are thrown back into the dryer by reverse flow of pulsating air. Generally the product filter are heated to avoid condensations of vapors in the filter bag.

- User friendly discharge valve design provides vacuum tight closing when the material is processed and quick opening lever facilities filling of bags when material discharge and packed.

- Breaker bars are incorporated in the RVPD to break the lumps where the product forms lumps during drying.

- Insulation with Cladding will provided on heating jacket/Limpet coil.

These dryers give optimum performance with very high heat transfer rates. These dryers have been successfully used for reaction, crystallization, and extraction operations in addition to the primary function of drying. Low temperature drying for heat sensitive product is possible.

Complete solvent recovery is possible with this Rotary vacuum paddle Dryer.

The Cantilever Model have following versatile features:

The Cantilever Model have following versatile features:

Full door opening for ease of operation, cleaning and validation.

Clean area installation possible with stainless steel partition wall between the process area and drives

The paddle dryer is also supplied with machined and mirror polished inside surfaces with PTFE Scrapers.