Liquid Solid Separation

DESCRIPTION

Our team of process experts work with you to define your requirement, evaluate feasibility, proceed through small scale trials and scale-up calculations.

From the smallest company to the largest system, from the simplest machine to the most complicated, we are here to help you define your needs.

Filter-dryers can be used for the following batch process steps:

Filter-dryers can be used for the following batch process steps:

- Filtration (formation of the cake)

- Cake smoothing

- Cake washing (piston- or reslurry washing)

- Vacuum drying

- Cooling

- Automated discharge

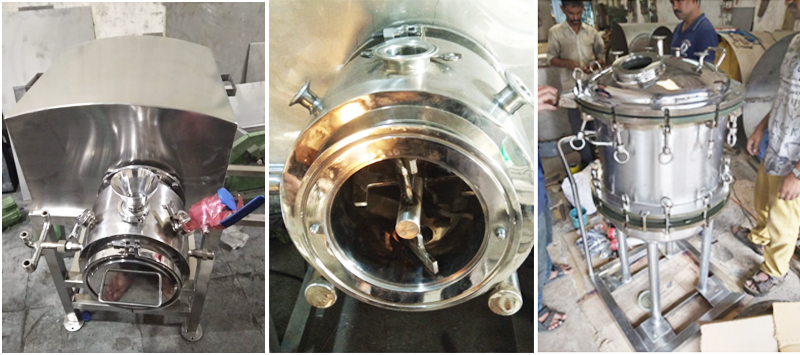

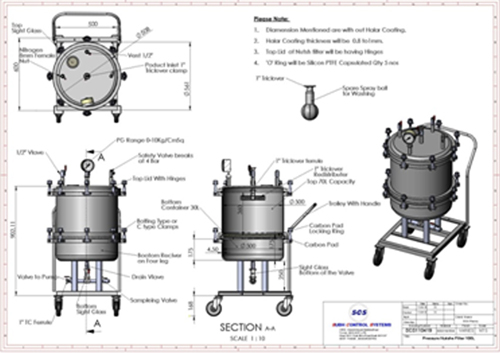

STATIC NUTSCHE FILTERS

Static liquid-solid separation – that is the purpose of Nutsche filters. Fitted with a filtration media at the bottom and suitable for vacuum of pressure applications, Nutsche filters are a larger scale version of the well-known lab Büchner filter.

Whether manufactured in glass, glass-lined steel, stainless steel or hastelloy, Nutsched filters all follow the same principle. A filter media is placed at the bottom of the vessel, allowing slurry to be loaded and the solids (usually crystals) to be separated from their mother liquor.

- Manual or automated Nutsche filters

- Filter dryers from pilot to production scale

- Glass, glass lined, stainless steel, hastelloy versions available

PRODUCTS

Products for solid – liquid separation are:

- Pocket filters (made of glass or stainless steel)

- Static Nutsche filters

- Pilot scale filter-dryers

RPVD Rotary Paddle Vacuum Dryer