Heat Transfer

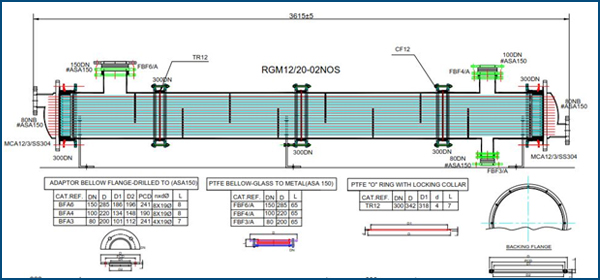

SCS heat exchangers provide the optimum solution for every requirement encountered in practice because of the wide range of types available. This applies not only to coil type heat exchangers, which are available as condensers, boilers and immersion heat exchangers, but also to shell and tube heat exchangers, which are designed for use with tubes in the widest possible range of corrosion resistant materials.

These items are widely used in the chemical, pharmaceutical and allied industries together with other applications such as food and drink production, dye works and electroplating. This is because of the special properties of borosilicate glass 3.3 and all the other materials used plus the fact that borosilicate glass 3.3 is an approved and proven material of construction for pressure vessels.

Reference should also be made in this context to the extreme reliability of the strong and high-duty coupling system used for all components. This is achieved throughout the whole range of nominal sizes by the use of the safety buttress end which has been designed specifically by taking into account the properties of the material coupled with a reliable flange system.

The complete range of standard heat exchanger components is described on the following pages. Non-standard components that can be supplied to special order are referred to in the respective product description.

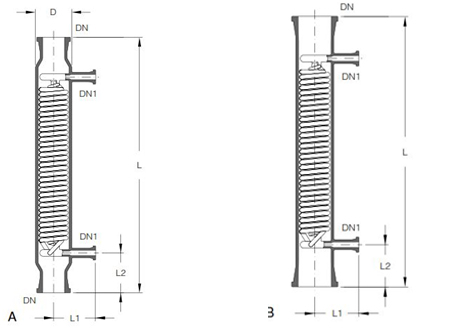

COIL TYPE HEAT EXCHANGERS

Unlike the shell and tube heat exchangers these items have the coil battery welded to the jacket. This is of importance for plant which has to conform to GMP requirements since it ensures that the product and the coolant cannot come into contact with each other.

Coil type heat exchangers are mainly used as condensers or coolers. They can, however, be used for heat transfer between liquids and gases in general. Turbulent flow is ensured even in the larger nominal bores since the coil layers are offset and fill the flow cross-section to a great extent.

Information on pressure drop in the coils together with performance data which can be used to estimate the heat transfer surface required .We would be happy to carry out detailed design work for you.