Reaction

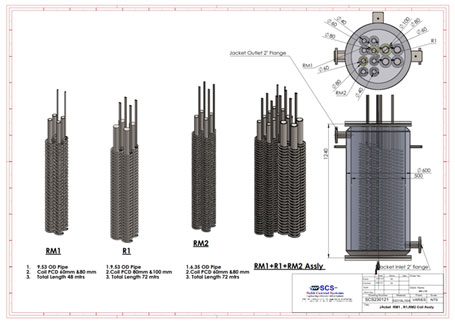

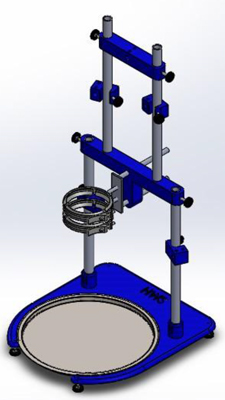

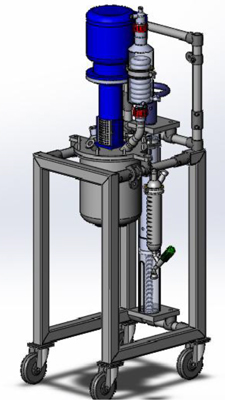

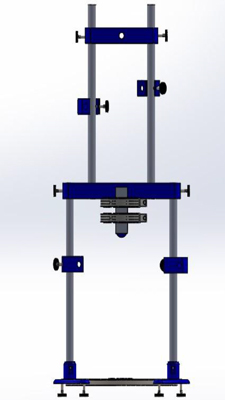

Lab Reactors And Jacketed Reaction Systems

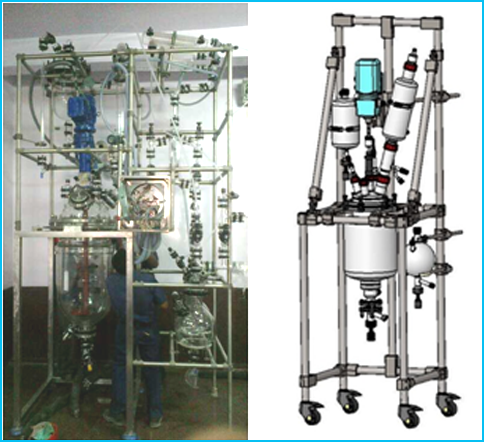

- Off-the-shelf, pre-configured Lab Reactors from 100 ml to 20 litres.

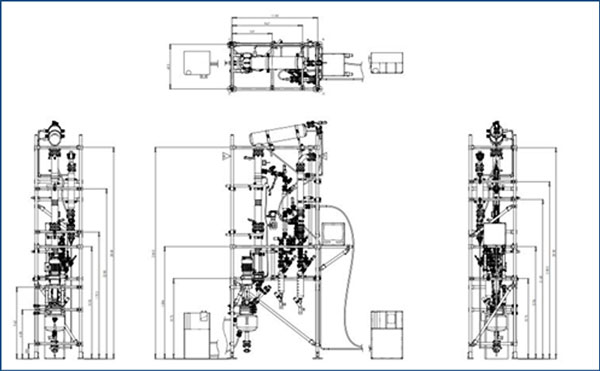

- Custom designed jacketed reaction systems and frameworks from 100 ml to 30 litres.

Subh Control Systems have been designing and manufacturing scientific glassware for over 15 years. Whether you require a multi-vessel process rig, a small bench top reactor or a complex parallel set-up, our team of design engineers and scientific glassblowers will be pleased to help with your project.

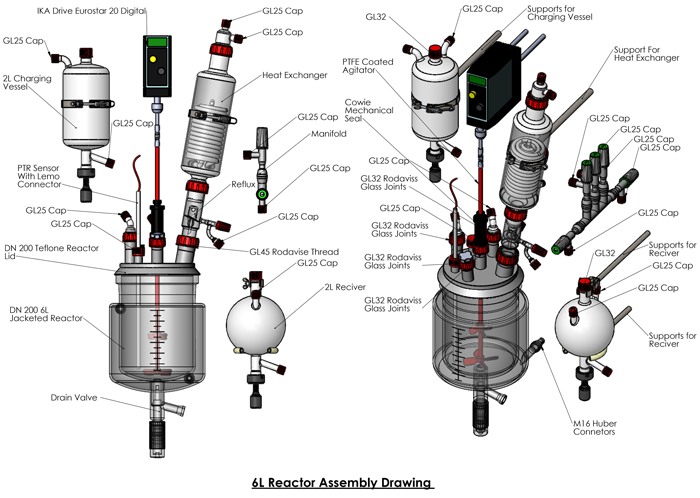

Glass Reactors – The Heart Of A Syntheses Plant

There is a large number of different types of glass reaction vessels available due to different the types of heating. Jacketed glass reactors up to 100l and reactors with immersion heaters up to 200l can be heated and cooled with a thermo fluid whereas spherical reactors up to 500l equipped with a electrical heating mantel can only be heated. For a reliable control of a reaction reliable mixing and reproducible heat transfer are as essential as tight operation towards the atmosphere. As the different requirements in this respect are given by the process to be carried out different types of stirrers and industrial stirrer drives are provided by Subh Control Systems to suit these different needs.

Especially advantageous is the baffle system with baffles fixed to the inside of the vessel to improve mixing considerably without blocking space for standard baffles fixed to the reactor cover. baffle system is available for all cylindrical glass reactors down to DN200. Since the baffle system for glass reactors is of the same type as for the glass-lined reactors the scale up from small pilot scale glass reactors up to huge production glass-lined reactors is eased.

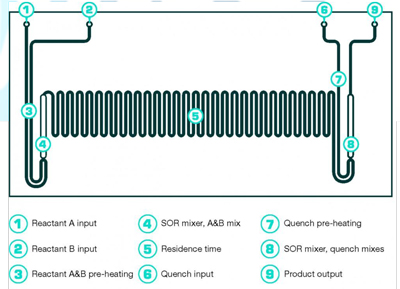

Flow Reactor (or Micro Reactor) is a device in which chemical reactions take place in micro channels. The Micro Reactor is usually a continuous flow reactor (contrast with/to a batch reactor). Micro Reactors offer many advantages over conventional scale reactors, including vast improvements in energy efficiency, reaction speed and yield, safety, reliability, scalability, on-site/on-demand production, and a much finer degree of process control.

Flow Reactor (or Micro Reactor) is a device in which chemical reactions take place in micro channels. The Micro Reactor is usually a continuous flow reactor (contrast with/to a batch reactor). Micro Reactors offer many advantages over conventional scale reactors, including vast improvements in energy efficiency, reaction speed and yield, safety, reliability, scalability, on-site/on-demand production, and a much finer degree of process control.